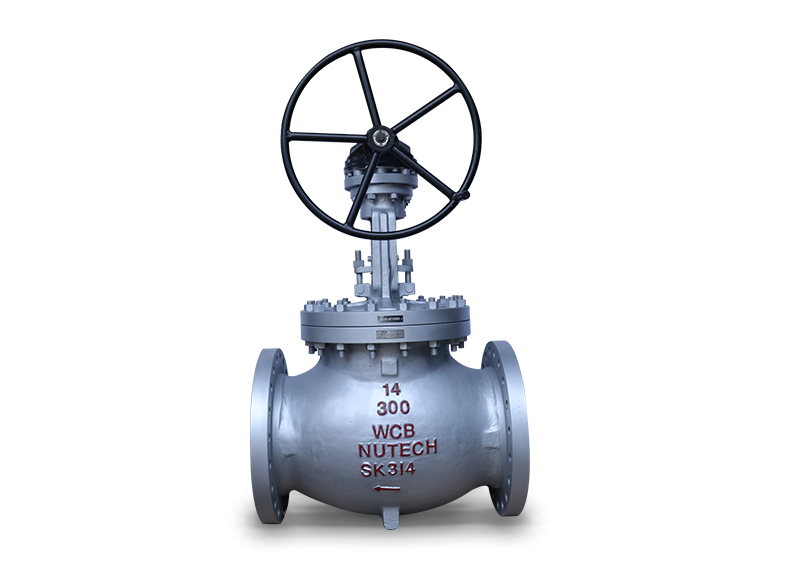

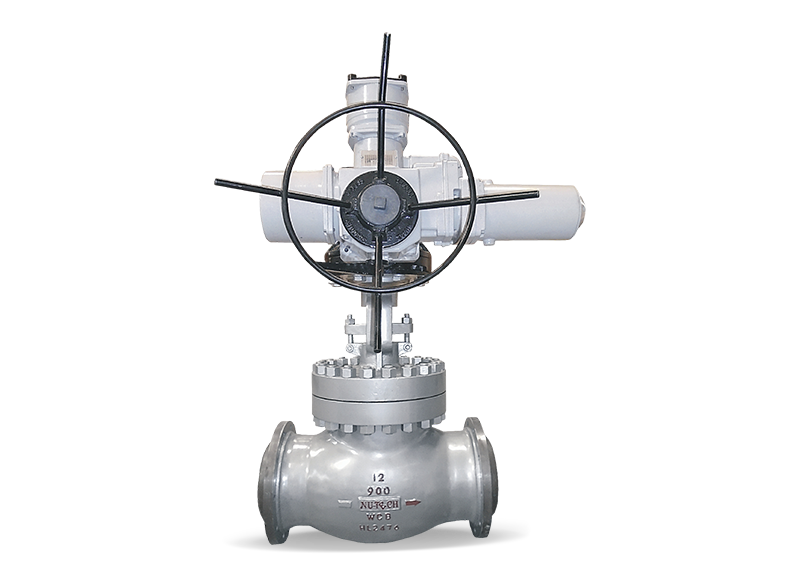

Cast Globe Valve

NU-TECH cast steel globe valves are designed and manufactured to provide maximum service life and dependability. All globe valves are full ported and meet the design requirements of American Petroleum Institute standard BSEN 1873 and generally, Conform to American Society of Mechanical Engineers standard ASME B16.34. Valves are available in a complete range of body/bonnet materials and trims.